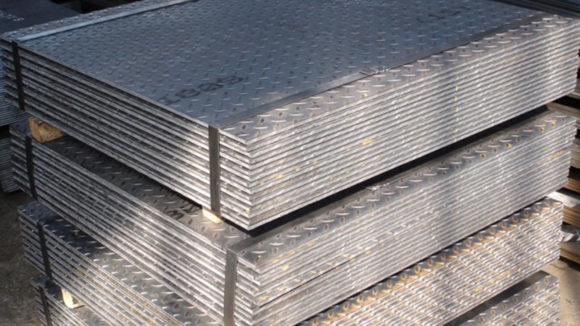

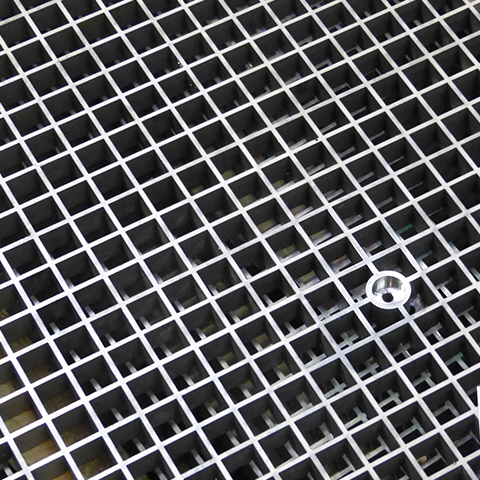

Tear drop plates and checker plates

Tear drop plates and checker plates belong to the covering plates and should primarily ensure slip resistance. They can also be used for decorative purposes.

Teardrop plates made of steel are characterized by individual, staggered tears. By arranging these tears an optimal slip resistance is achieved because the water can run off very well. Teardrop plates made of stainless steel have a similar embossing as the version made of rolled steel. With teardrop plates made of aluminium one speaks of pinned plates.

Checker plates made of steel, on the other hand, have a diamond-shaped pattern from which accumulated water cannot run off. Therefore, checker plates are preferably used in low-precipitation areas such as the Middle East.

Dimensions

Qualities

Factory / works certificate

If required, the cuts can be provided with a works certificate / WZ 2.2 or acceptance test certificate / APZ 3.1 according to EN 10204. External approvals / APZ 3.2 by the TÜV as well as the common classification societies (ABS, BV, GL, LR etc.) are also possible. In addition, we have the following tests carried out and provided with a certificate: Ultrasonic test / US test, weld-on bending test / ABV

Possible processing

- Shearing / burning

- beveling

- shotblasting and primering

Custom cut

Tear drop plates and checker plates can also be cut to size

Häufig verwendete Bezeichnungen: Alutränenblech, Aluwarzenblech, Alu-Duettblech, Alu-Quintettblech, Edelstahltränenblech, Alu-Riffelblech, Edelstahlriffelblech, Riffelblech, Riffelblechzuschnitt, Tränenblech, Tränenblechzuschnitt