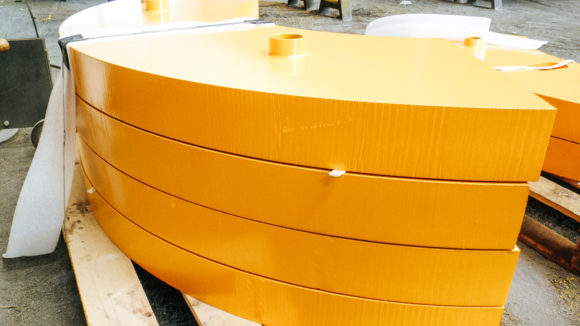

Flame cuts

Oxygen flame cutting is particularly suitable for the economical separation of sheet metal and steel parts with large thicknesses (up to 1500 mm possible). The surface of the sheet to be processed is heated to ignition temperature by a flame on a CNC-controlled oxy-fuel burner. Then the material is burned by the addition of oxygen. The oxygen blows the liquid flame cutting slag out of the joint. The remaining slag at the joint exit creates the so-called cutting burr, which must be removed before consignment (deburring).

Dimensions

Qualities

Inspection certificates

If required, cuttings can be provided with test report 2.2 or mill’s test certificate (mtc) 3.1 according to EN 10204. Third party insprection 3.2 by TÜV as well as the common classification societies (ABS, BV, GL, LR etc.) are also possible. In addition, we have the following tests carried out and provided with a certificate: Ultrasonic test / US test, weld bead bend test

Additional processing:

- beveling up to 100 mm thickness

- shotblasting and primering

- straigthening / levelling

- heat treatment

- drilling, milling, grinding, chamfering/bevelling

- materials testing

Häufig verwendete Bezeichnungen: Ankerplatten aus Stahl, Autogenbrennen, Autogenbrennteile, autogengebrannte Zuschnitte, Autogenschneiden, autogenes Brennschneiden, Autogenschneidteile, Autogenzuschnitte, Blechzuschnitte, Blechzuschnitte aus Stahl, Blechzuschnitte aus Edelstahl, Brennschneiden, Brennteile, Brennzuschnitte aus Hardox, Brennzuschnitte aus Stahl, Cortenzuschnitte, Cortenstahlzuschnitte, Fixmaßbleche, Formteile, Formzuschnitte, Gegengewichte aus Stahl, Grobblechzuschnitte, Kesselblechzuschnitte, Kontergewichte aus Stahl, Maßbleche, Riffelblechzuschnitte, Stahlzuschnitte, Tränenblechzuschnitte, verschleißfeste Brennzuschnitte, warmfeste Brennzuschnitte