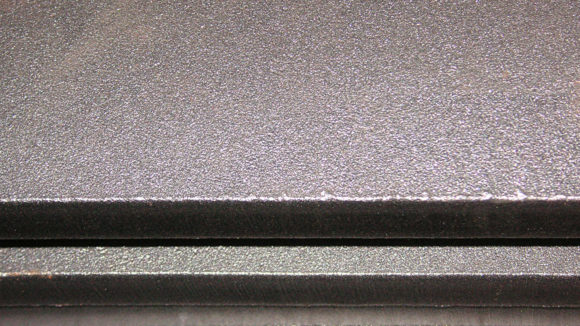

Shotblasting / primering

When sandblasting, old layers of paint, rust, scale residues or oil and grease traces on steel parts are professionally removed. The blasting system and blasting agent dosage are selected so that the required surface quality is created.

In addition to the preparation of the workpiece surface, the application of a robust, versatile primer for a particularly effective atmospheric corrosion protection is also included – if desired in a RAL tone of your choice.

We are broadly based

further processing

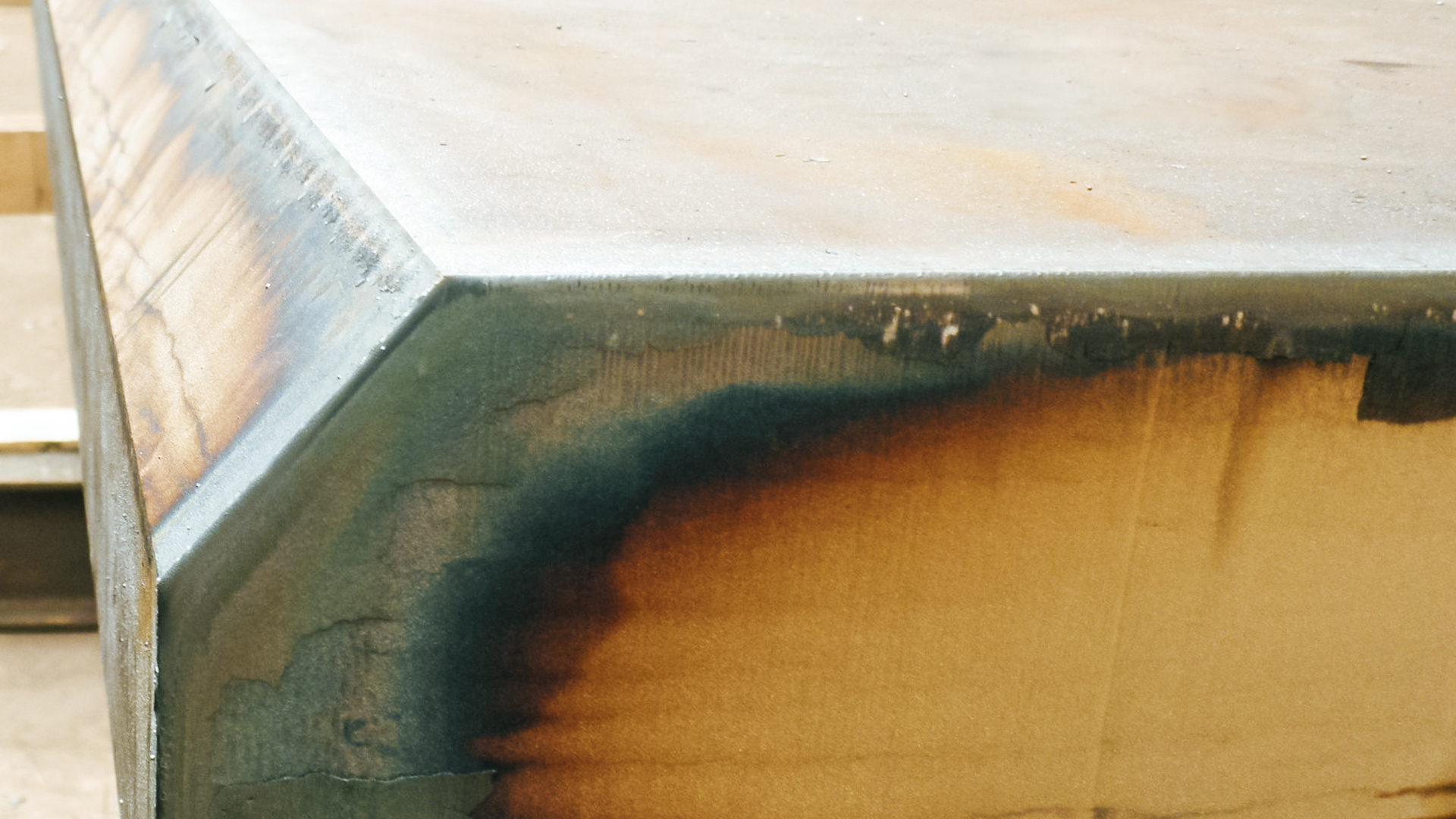

Straigthening

In thermal cutting processes, blanks can deform due to the action of heat. Depending... mehr

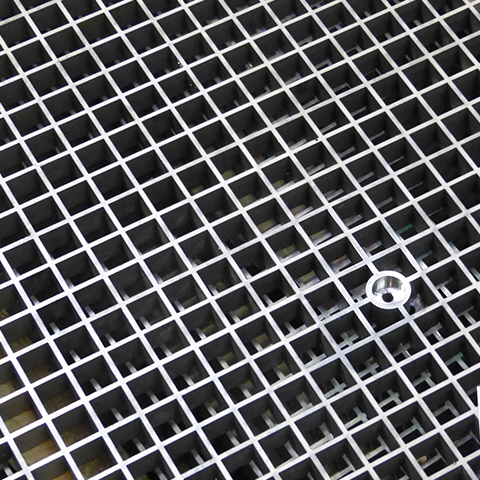

Chamfering

In thermal cutting processes, blanks can deform due to the action of heat. Depending... mehr

Round rolling

Round rolling is part of the bending process. The blank to be machined is usually... mehr