Straigthening

In thermal cutting processes, blanks can deform due to the action of heat. Depending on the stresses in the prior material (sheet), the cutting temperature and the cross-section of the blank, different degrees of deformation arise. If the flatness deviation is too high for the desired application, it is advisable to report the blanks using hydraulic presses.

Depending on the requirements, the straightening process enables the flatness values listed in EN10029 class N, class S and moreover – for highest demands – flatness up to 1 mm over 1 m measuring length.

We are broadly based

further processing

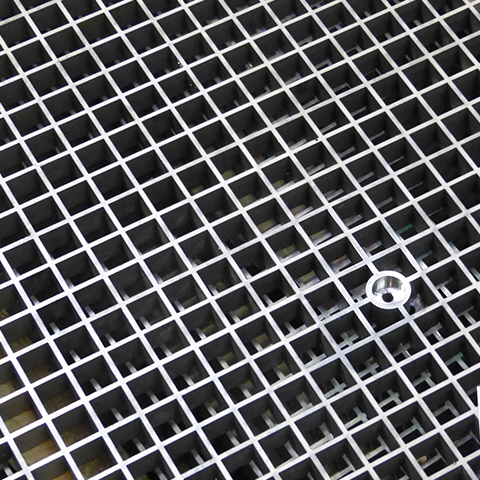

Shotblasting/primering

When sandblasting, old layers of paint, rust, scale residues or oil and grease traces ... mehr

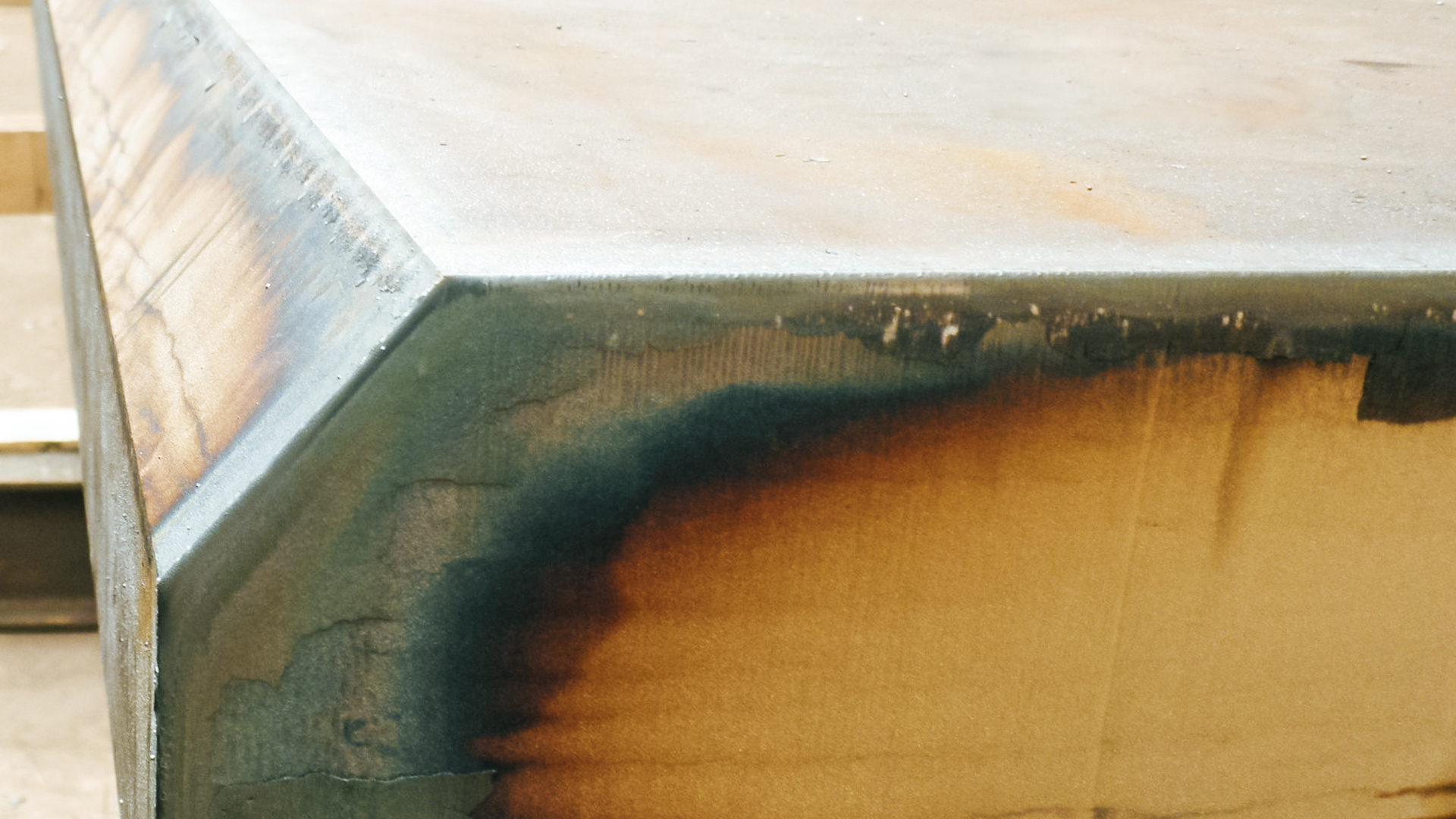

Chamfering

In thermal cutting processes, blanks can deform due to the action of heat. Depending... mehr

Round rolling

Round rolling is part of the bending process. The blank to be machined is usually... mehr