Heat treatment

When it comes to the heat treatment of sheets and blanks, three different processes are relevant: normalising, stress relief annealing and tempering. They differ in the level of the temperature and the length of stay in the annealing furnace.

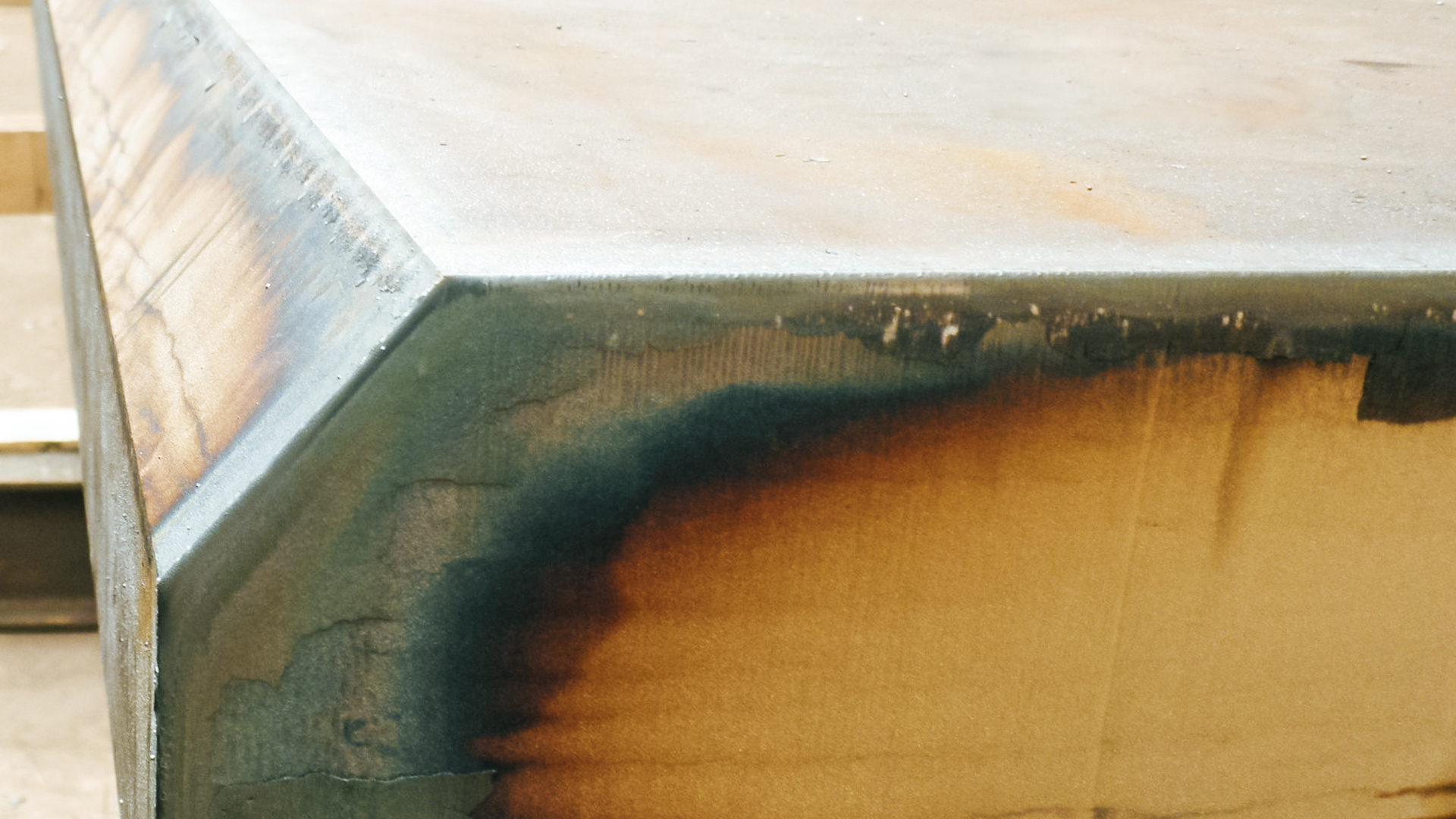

Normalising: Normalising: Normalising makes it possible to bring uneven or coarse-grained structures into a uniform and fine-grained state. Depending on the carbon content of the steel, the annealing temperature is usually between approx. 800 and 950° C. Normalising is used, for example, after oxygen flame cutting. The hardening on the cut surfaces caused by the firing process is eliminated – for easier mechanical processing.

Stress relief annealing: internal stresses can arise in a component, especially after mechanical processing such as straightening, bending or machining. Stress relief annealing reduces or eliminates these residual stresses. The annealing temperatures are between approx. 480 and 680° C.

Quenching and Tempering: Quenching and Tempering gives steel a higher strength and hardness. In the heat treatment process, the steel is quenched from a temperature of approx. 800 to 900 ° C by air, water or oil and then tempered at approx. 150 ° C.