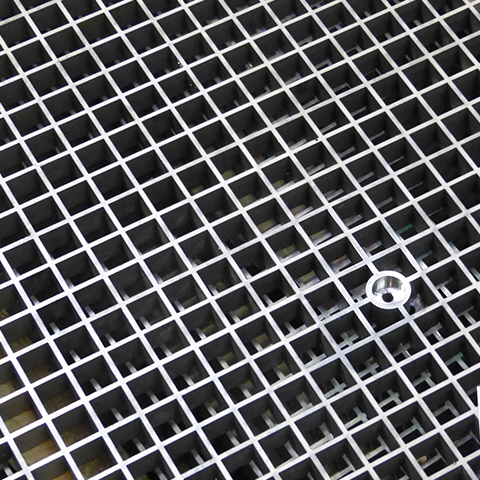

Round rolling

Round rolling is part of the bending process. The blank to be machined is usually moved between three rollers and thus bent into the desired shape.

The shaping of workpieces by round rolling is relatively gentle. This means that one process can often be used several times without affecting the material. The choice of the suitable round roller depends on the material thickness, diameter, length and quality.

In addition to classic round rolling, we also offer the production of workpieces with a round and, at the same time, angular contour – a combined machining process for round rolls and edges is used.

we are broadly based

further processing

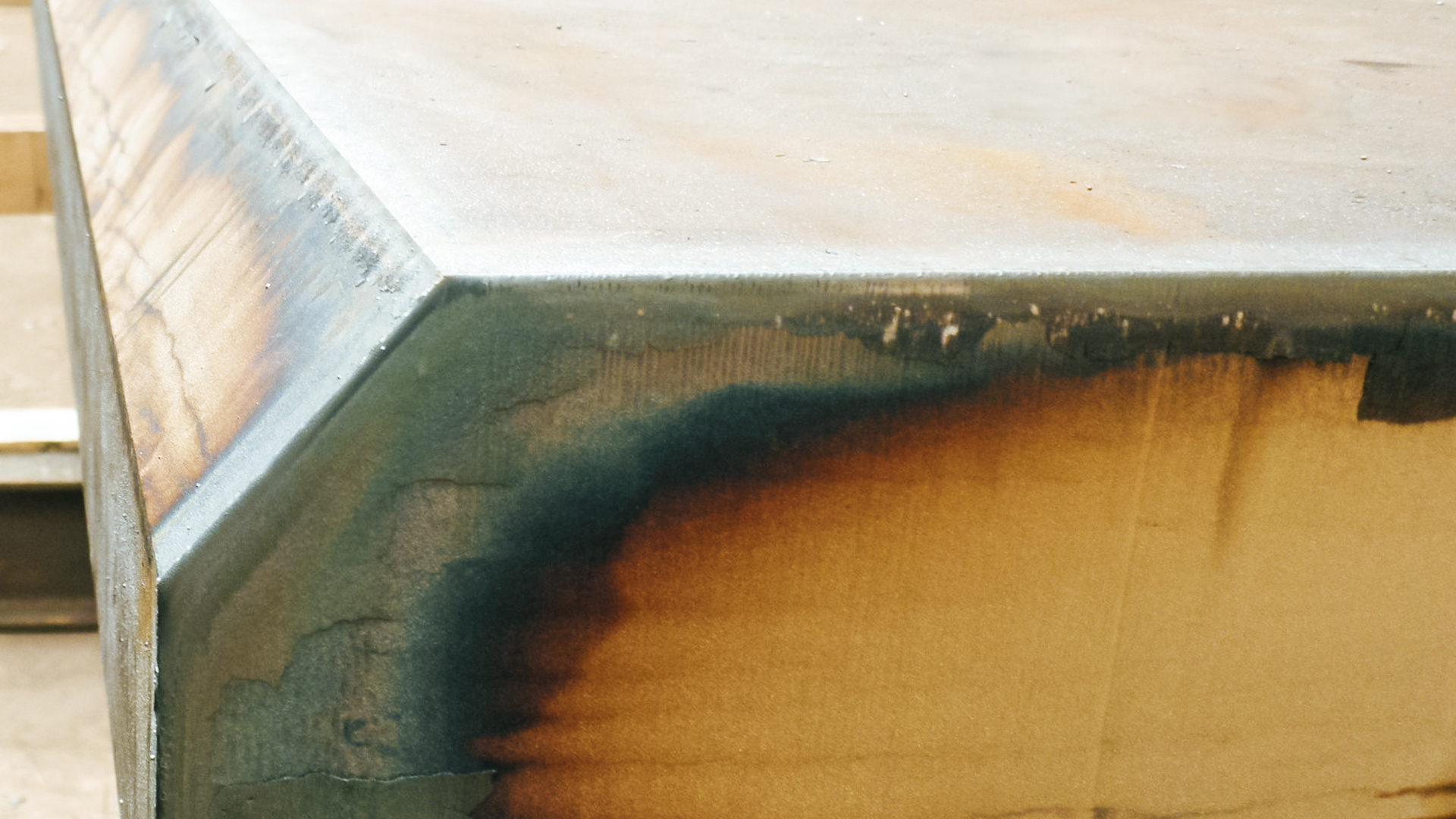

Shotblasting/primering

When sandblasting, old layers of paint, rust, scale residues or oil and grease traces ... mehr

Straigthening

In thermal cutting processes, blanks can deform due to the action of heat. Depending... mehr

Chamfering

In thermal cutting processes, blanks can deform due to the action of heat. Depending... mehr