Water jet cutting

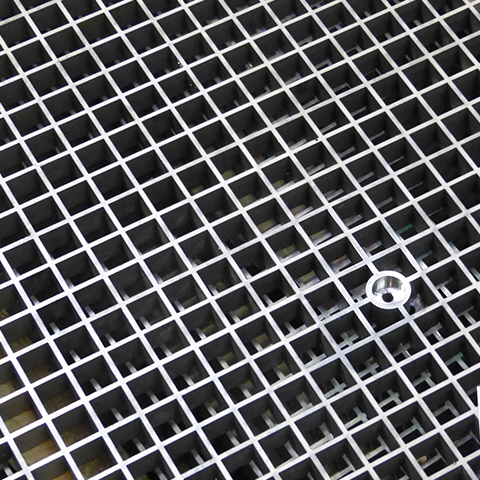

Water jet cutting belongs the cold cutting processes and enables the separation of sheet metal from a wide variety of materials such as steel, stainless steel or aluminium in thicknesses of up to 200 mm. In contrast to the thermal cutting processes such as oxy-fuel cutting, plasma cutting or laser cutting, no heat is exerted on the cutting zone when cutting with a water jet. In this way, very tight tolerances can be precisely cut without changing the structure or hardening the edge zones. Subsequent mechanical processing is usually not necessary. Another plus: the cleanliness of the cut surfaces – almost without cutting burr.

In water jet cutting, water is directed onto the sheet to be cut using a hydraulic pump with a very high pressure of up to over 6500 bar. Quartz sand, garnet and corundum are mostly used as abrasives. The cutting accuracy is mainly controlled by the speed.

Dimensions

Qualities

Inspection certificates

If required, cuttings can be provided with test report 2.2 or mill’s test certificate (mtc) 3.1 according to EN 10204. Third party insprection 3.2 by TÜV as well as the common classification societies (ABS, BV, GL, LR etc.) are also possible. In addition, we have the following tests carried out and provided with a certificate: Ultrasonic test / US test, weld bead bend test

Häufig verwendete Bezeichnungen: Abrasiv-Wasserstrahlschneiden, Alu-Wasserstrahlzuschnitte, Blechzuschnitte, Blechzuschnitte aus Stahl, Blechzuschnitte aus Edelstahl, CNC-Wasserstrahlschneiden, Cortenzuschnitte, Cortenstahlzuschnitte, Edelstahlwasserstrahlzuschnitte, Edelstahlzuschnitte, Fixmaßbleche, Kesselblechzuschnitte, rostfreie Wasserstrahlzuschnitte, Stahlzuschnitte, VA-Wasserstrahlzuschnitte, VA-Stahl, VA-Zuschnitte, verschleißfeste Wasserstrahlzuschnitte, warmfeste Wasserstrahlzuschnitte, Wasserstrahlschneiden, Wasserstrahlschneidteile, Wasserstrahlteile, Wasserstrahlzuschnitte, Wasserstrahlzuschnitte aus Edelstahl, Wasserstrahlzuschnitte aus Stahl, Wasserstrahlzuschnitte aus Hardox