Plasma cutting

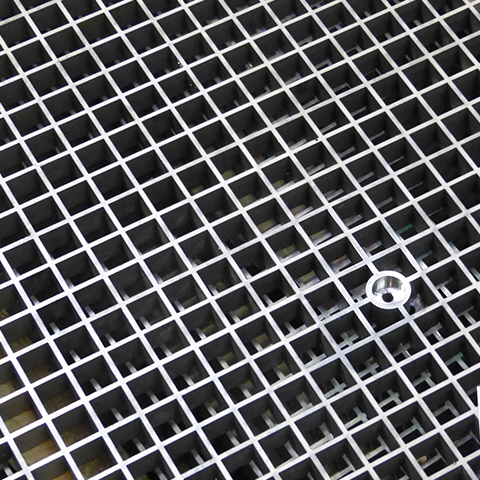

Plasma cutting is a very clean and precise cutting process and – unlike oxyacetylene cutting – also enables the cutting of stainless steel sheets. Thanks to the comparatively higher cutting speed, the throughput times can also be reduced, especially with large cuts. The processing takes place as follows: In the plasma cutting system, compressed gas is first sent through a very small channel. In the middle is a negatively charged electrode, which is supplied with current. As soon as the nozzle touches the metal, a spark is created between the electrode and the metal. The spark heats the shielding gas to plasma – this generates a jet that is over 15,000° C hot. If the plasma jet comes into contact with metal, it becomes a molten slag.

Dimensions

Rolled steel

Stainless steel

Qualities

High yield strength fine grained steels according to EN 10025-6

Inspection certificates

If required, cuttings can be provided with test report 2.2 or mill’s test certificate (mtc) 3.1 according to EN 10204. Third party insprection 3.2 by TÜV as well as the common classification societies (ABS, BV, GL, LR etc.) are also possible. In addition, we have the following tests carried out and provided with a certificate: Ultrasonic test / US test, weld bead bend test

Häufig verwendete Bezeichnungen: Blechzuschnitte, Blechzuschnitte aus Stahl, Blechzuschnitte aus Edelstahl, CNC-Plasmaschneiden, Cortenzuschnitte, Cortenstahlzuschnitte, Edelstahlplasmazuschnitte, Edelstahlzuschnitte, Fixmaßbleche, Kesselblechzuschnitte, Plasmabrennen, Plasmabrennteile, plasmagebrannte Zuschnitte, Zuschnitte, rostfrei, Plasmaschneiden, Plasmaschneidteile, Plasmateile, Plasmazuschnitte, Plasmazuschnitte aus Edelstahl, Plasmazuschnitte aus Hardox, Plasmazuschnitte aus Stahl, Maßbleche, Riffelblechplasmazuschnitte, Stahlzuschnitte, Tränenblechplasmazuschnitte, VA-Plasmazuschnitte, VA-Stahl, VA-Zuschnitte, verschleißfeste Plasmazuschnitte, warmfeste Plasmazuschnitte